Why is supply chain digitisation a must for your business?

Logistics & Supply Chain

201 week ago — 11 min read

Supply chain digitisation has been a buzzword for a while and the pandemic has made many businesses realise that it is now critical to operate efficiently. According to several reports, COVID-19 has considerably accelerated digital transformation of businesses and their supply chains.

Before we to talk about why supply chain digitisation is a must for your business, let’s understand what the term supply chain means.

What is a supply chain?

A supply chain is a complex ecosystem which is painstakingly nurtured by businesses, after significant investment of time and capital. This complex ecosystem enables a business to make its products reach the end consumer. The typical entities involved in the supply chain are brand/manufacturer, trade partners, distributors, retailers and the end customers.

Why is supply chain efficiency important?

An optimised, efficient supply chain is integral to ensure the availability of the right product, at the right time, in the right quantity. It leads to better planning, reduced wastage, lower working capital requirement and increased profitability. Above all, this will make the business, future proof.

Non-digital Supply Chain Vs Digital Supply Chain

Non-digital Supply Chain

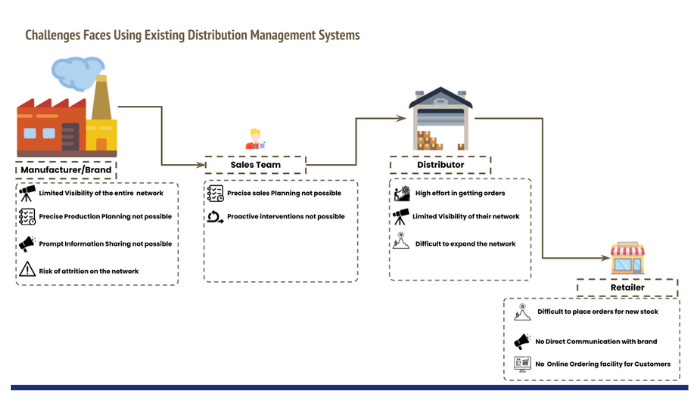

A traditional, non-digital supply chain or semi digitised supply chain typically connects the top layer of the distribution network, resulting in no or at best historic visibility of stock, sales, consumption patterns across the network. Furthermore, the trade partners, especially further down the distribution network, have to go through a cumbersome process to order supplies for their business or wait for the salesperson to visit them. Resulting either in business loss for the trade partners or in some cases, the trade partners switching to a competitor, leading not only to loss of business but also of geographic territory for the brand manufacturer. Furthermore, any non-digitised system is prone to human error and manipulation, which can lead to serious lapses in planning, thereby causing huge losses. Needless to mention because of its non-digital nature, expansion of the distribution network requires significant time and effort.

Let's understand the scenario in a better way with an example:

The Network Setup

Suppose an enterprise is a manufacturer of FMCG products, and they have 200 distributors spread across the country. To manage and get orders from these distributors, the company has a 10-person sales team. Each distributor is further connected to 200 retailers each. To manage and get orders from retailers, each distributor has employed a 10-person on ground sales team. So overall, the distributor network has about 40K trade partners, requiring 2,200 people to operate and manage it.

How does the ordering happen?

The business’ sales team will connect and coordinate with each distributor to either get orders offline or on the business’ ordering system. This will require frequent follow-ups and will provide limited and historical visibility on stock, sale etc.

To get orders from retailers, the distributor team has to visit each retailer's store, review the stock and create a purchase order, which is an effort heavy and slow process, which also creates an avenue for retailer takeover by a competitor. Furthermore, being a totally human dependent process, it creates grounds for manipulation and bias.

Digitised Supply Chain

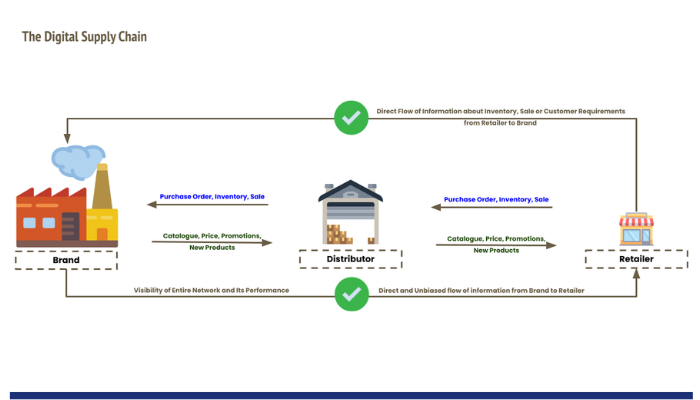

A digital supply chain offers a digitised, end to end, perpetual and non-human dependent network, which connects each and every trade partner in the distribution network, thereby giving a real time visibility of stock, sales, consumption pattern, geographic spread etc. Business to trade partner or inter trade partner ordering becomes extremely easy and convenient. Two-way communication with the trade partner becomes possible, allowing the business to easily conduct surveys, seek feedback, undertake promotional and merchandising campaigns etc. Above all, it allows a business to plan better, execute easily and track efficiently, resulting in reduction of cost and wastage and increase of profitability.

Let's understand the scenario in a better way with an example:

The Network Setup

Enterprise is a manufacturer of FMCG products, and they have 200 distributors spread across the country. To monitor and manage these distributors, the company has a two-person sales team. Each distributor is further connected to 200 retailers, each. To monitor and manage the retailers, each distributor has employed two people. So overall the distributor network has about 40K trade partners, requiring just 402 people to operate and manage it.

How does the ordering happen?

As each and every trade partner is connected through the digital network, ordering has become very easy. So, if a distributor has to order from the business, they can either use the system to generate the list of products, with stock below the reorder level and process the order at a click of a button or they can visit the business’ digital catalogue and place the order as per their requirement.

The conventional or non-digitised distribution network operates on the principles of price discount commitment, credit understanding and minimum purchase commitment, the same principles can also be applied through the digital distribution network. For instance, if a distributor has an understanding with the business that they will get 10% off on MRP and can buy products worth 1 lakh on credit for a period of 30 days, with a minimum purchase commitment from their side of 10 units per product. While placing the order, all these conditions can be applied through the digital distribution system.

Order placement by retailers is equally simplified - they don’t have to wait for a sales person to visit their store, they can simply place an order with the distributor using their smartphone as per their requirement and convenience. Additionally, through the digital distribution network, the retailer will also have capability to offer online ordering facility to their customer, opening a new sales channel for them and allowing them to gain back the sales which they may have lost to online competitors.

Advantages of a Digitised Supply Chain

-

Gain Real Time Visibility, Update and Control of the entire Distribution Network

In the modern business environment, having real time visibility and knowledge is crucial for the survival and growth of any organization. Without having the right information, it is impossible to make the right decisions, Furthermore, it is also difficult to judge the health of the business without having the right information. With a Digital Distribution Network, get real time visibility, knowledge and control over your distribution network.

-

Owning every bit of the Distribution Network

Building a distribution network is costly and time consuming and losing a portion of it can jeopardise not only profitability but also the existence of a business. Therefore, it is important that a business not only stays in touch with each and every trade partner but also closely monitors vital stats to avoid any unwanted movement or takeovers of Trade Partners by competition. Thus, with the Digital Distribution Network, even if a trade partner moves out, the rest of the network associated with that trade partner will stay with your business.

-

Reducing Operating Expenses and Cost

Operating a distribution network efficiently requires a number of human resources and a significant amount of time. However, with the Digital Distribution Network the same processes can be managed and executed more efficiently and easily, thereby greatly reducing the human resources requirement. Reduction in human intervention will also make the system more accurate and unbiased, which will help significantly reduce cost of operations for the business, as well as associated trade partners.

-

Increasing profitability by reducing wastage

The Digital Distribution Network will not only help in reducing the human resource cost but will also help in better production and sales planning, thereby reducing the working capital requirement, wastage and significantly reducing the dead stock. Thus, increasing the profitability of the organisation as well as trade partners. Furthermore, as the Digital Distribution Network also makes ordering easy and provides additional sales channel to the trade partner which helps in increasing profitability.

-

Simplifying Inter-Trade Partner Ordering

With the Digital Distribution Network, a trader partner will be able to get orders from their trade partners easily and more efficiently. As now they will be able to place orders digitally without waiting for the sales personnel to visit their store. Furthermore, the system will also provide analytical capability to trade partners, which will allow them to monitor ordering trends of their trade partners and any deviation can be highlighted and required intervention can be undertaken immediately.

-

Growing End Customer Sale by Trade Partners

Almost every year about 15 to 20 per cent of the brick-and-mortar business is lost to online because of the changing customer buying behaviour and because of this the end customer facing trade partners are losing quite a lot of business. With the Digital Distribution Network, a trade partner will be able to create an eCommerce store for their business and offer online ordering facility to the end customer, thus not only increasing their and brand’s sales but also making their business future proof.

-

Improving Trade Partner Relation and Connect

The Digital Distribution Network is not only about making the distribution network more efficient but also about nurturing positive engagement with the entire trade partner community. Therefore, a brand or manufacturers will be able to easily communicate with their entire trade partner network and also offer GlobalLinker’s other offerings to make their business growth journey simpler, more profitable and enjoyable.

To understand how to easily digitise the supply chain for your B2B or B2C business, I conducted an exclusive webinar on May 20, 2021. Watch the webinar recording below.

To explore business opportunities, link with me by clicking on the 'Connect' button on my eBiz Card.

Image source: shutterstock.com

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views, official policy, or position of GlobalLinker.

Posted by

GlobalLinker StaffWe are a team of experienced industry professionals committed to sharing our knowledge and skills with small & medium enterprises.

Network with SMEs mentioned in this article

View GlobalLinker 's profile

Most read this week

Comments (1)

Share this content

Please login or Register to join the discussion